Services.

Better plant engineering starts with the identification of optimization potentials and the development of your individual optimization concept – we make you ready for your future challenges.

ePOT

ePOT

You are not sure of your optimization potential? Our process experts help you finding potentials and identifying bottlenecks.

Details

eCON

eCON

Do you appreciate help in tapping your full plant potential?

We support you in the development of customized, innovative optimization concepts.

Details

eCHECK

eCHECK

Everything tested and ready for the implementation of your plant optimization? We develop feasible solutions and take care about the integration into your plant.

Details

eSERV

eSERV

Do you see a need to increase your plant efficiency? Benefit from our expertise in pyroprocessing, drying and grinding.

Details

eSIM

eSIM

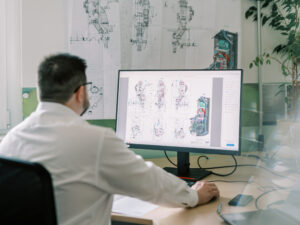

Do you want to better understand your plant process? With simulations, we give you a deeper look inside your plant.

Details

eTRIAL

eTRIAL

Are you facing new separation challenges?

Test runs in our in-house technical center help you to evaluate the options.

Details

● Other services

With our engineering services, we make you ready for your future challenges and integrate our products and system solutions into your plant in the best possible way – Get an overview.

Solutions

Solutions

The combination of our ideas and innovative optimization concepts with the client's requirements and needs creates finest solutions.

Details

Products

Products

Decades of engineering experience as well as attention to detail form the foundation for modifications of high process engineering quality - It's often the small details that make the difference.

Details

● Contact us

Let's talk about your project.

We would be happy if you share your plans with us – and if we can do our part.